Transmission belt is very significant in power transmission frameworks. It can create a lot of force during the functioning system. Simultaneously, it might likewise misfortune energy. Presently let us see something about the power transmission belts. Power transmission proficiency and parasitic sitting misfortunes in belt machine components have been considered for more than 50 years. Proficiency, slip, and temperature portray the presentation of huge rural belts utilized in the requesting impetus and grain detachment utilizations of high limit consolidates. Both cogged and wrapped belts show efficiencies over 90%, albeit cogged belt for the most part show higher productivity, lower slip, and cooler temperatures. Cogged efficiencies are over 94% all through the application power range.

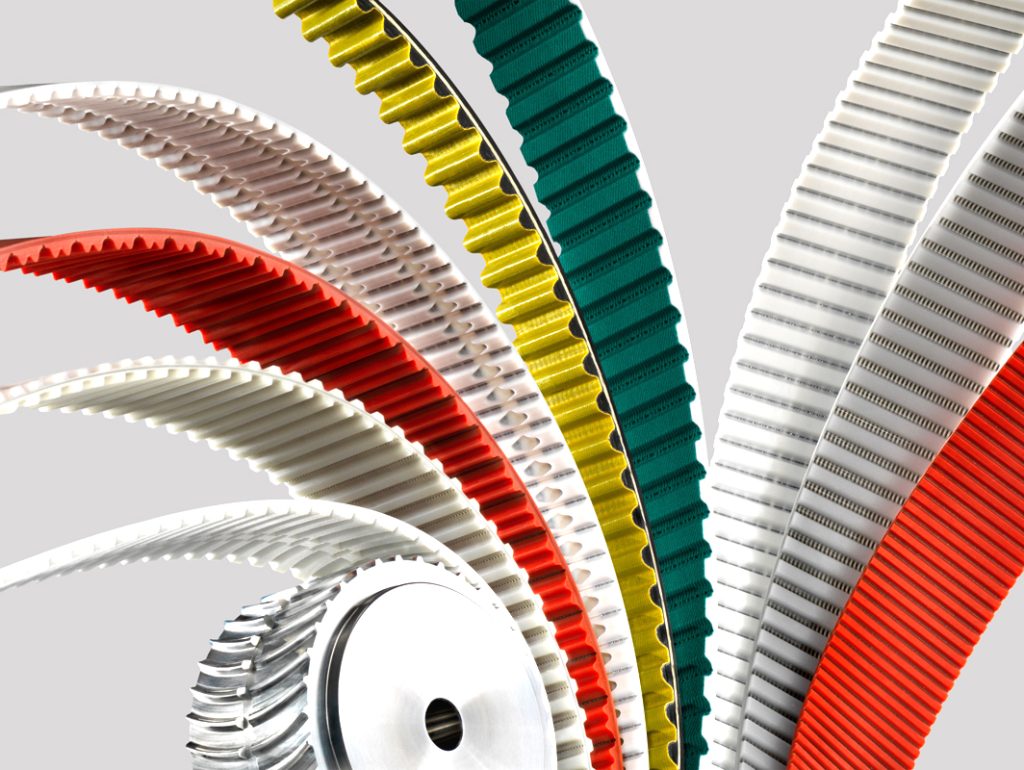

Standing by power misfortunes rely upon pressure, breadth, speed, and width, and so forth. The strain impact results from frictional sliding as a belt enters and leaves a pulley; though, the breadth reliance is an outcome of twisting hysteresis as a belt flexes from straight range to bended pulley ways. Since pulley speed controls the pace of frictional and hysteretic energy dissemination, fueling loss is basically relative. The impact of belt width is expected to both expanded frictional and bowing misfortunes coming about because of numerous industrial belts, bigger industrial V-belt cross areas, and more extensive V-ribbed and simultaneous correas de transmission . What’s more, the bowing hysteresis is the chief component deciding power misfortune examinations between cross segments. Thusly, because of expanded adaptability over plain base belts industrial V-belt cogged developments require the least energy and had at lower fevers under no heap. Industrial Vee and Ribbed belts are roughly 75% represented by the standing by misfortunes; while sitting misfortune represents around 50% of the coordinated belt transmission misfortunes.

The cogged belts showed lower slip level further increases its proficiency and temperature execution. Industrial Vee and V-ribbed belts, sizes and developments are contrasted for changing breadths and V-ribbed and cogged benefits being most prominent at more modest widths. The frill belts temperature execution is introduced as a component of slip and force levels. Cogged efficiencies are over 94% all through the application power range.

As per the above happy, the significant piece of belt energy misfortune during influence transmission is credited to parasitic twisting hysteresis and sliding grinding. The cogged development which limits the hysteretic part of parasitic misfortune yields the best productivity in each industrial test. Despite the fact that there are many burdens about the transmission belt, it actually assumes a somewhat significant part in the power transmission.